There are only a handful of heavy-duty trucks available on the market stateside, including the Ford F-350, the Chevrolet Silverado 3500HD, the GMC Sierra 3500HD, and the Ram 3500. The Silverado and Sierra are mostly identical aside from minor details, so you only really have three options. Here’s why a properly-equipped Ram 3500 is the most likely of the three to last to 250,000 miles or greater.

The Ram 3500 has become synonymous with reliability in commercial applications because of one key differentiator: the Cummins turbo diesel engine. With the right care, these diesel engines are designed to last a lifetime, while also producing over 1,000 pound-feet of torque in high-output specifications. Let’s break down how and why the Ram 3500 and its Cummins engine have gained a reputation as one of the most reliable one-ton work trucks you can buy.

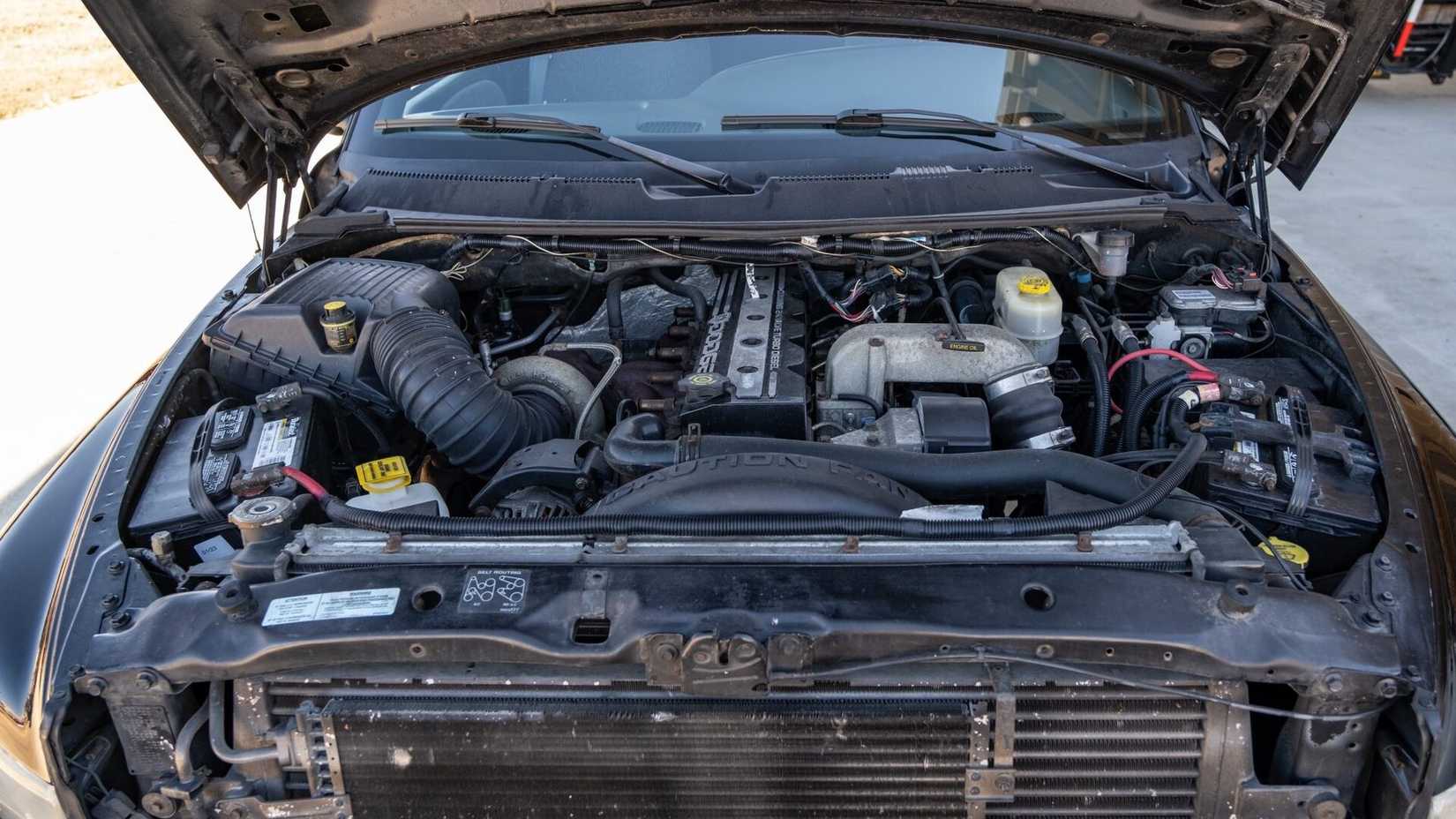

The Cummins Diesel Engine Is The Perfect Workhorse

Before the introduction of the Cummins diesel engine in the heavy-duty Ram Pickup truck, Dodge depended on the Chrysler RB big-block V-8 engine for commercial applications up until the late 70s. The Chrysler RB engine was discontinued in the 80s, and instead of developing a new big-block engine platform, Dodge teamed up with engine manufacturer Cummins. Dodge’s strategic partnership provided the 5.9-liter Cummins B Series diesel engine for use in the heavy-duty Ram Pickup moving forward. This collaboration proved to be one of the most important and successful partnerships in commercial truck applications.

The Introduction Of Cummins Diesel

Cummins was no random newcomer to diesel technology, but rather a well-recognized pioneer that has been producing diesel engines for over a century. The American company built its first diesel unit back in 1919, and the Cummins turbo diesel was introduced as part of the heavy-duty Ram Pickup line-up in 1989. Compared to its diesel contemporaries offered at the time, the Cummins unit was the most advanced power unit available. While Ford and Chevrolet units only offered indirect injection diesel engines, the Cummins diesel unit featured direct injection, a significantly more efficient fueling method. Ford and Chevy’s diesel engines were naturally-aspirated V-8 units, while Cummins’ engine was a turbocharged inline-six. Yet, how is an inline-six capable of providing better power, efficiency, and reliability than a V-8 engine? Let’s explain.

Why Turbo Inline-Sixes Are Built For Heavy-Duty Applications

Despite less displacement and fewer cylinders than its rivals, the 5.9-liter Cummins diesel proved to be the best heavy-duty powertrain available on debut. The inline-six engine inherently has a greater balance than a V-8 engine and is simpler to produce. An inline-six engine is also often lighter than V-8 counterparts, and packaging doesn’t tend to be as significant an issue in commercial or heavy-duty applications. As a result, inline-six engines are ideal as they offer great power-to-weight ratios and can still accommodate larger displacement sizes if needed. Yet, it is the introduction of turbocharging into the equation that truly elevated the overall capability of the inline-six engine in this application.

Diesel engines are known for high torque and low RPM operation. The lower the revs an engine produces, the less stress and heat are also produced. The less stress an engine receives, the longer a power unit will tend to last. Turbocharging plays perfectly into this formula as the right-sized turbo can optimize torque production in the low RPM region where commercial diesel engines tend to operate. By the late 90s, the 5.9-liter Cummins turbo diesel produced over 400 pound-feet of torque at a mere 1,400 RPM, an absolute dream power output for commercial applications. For comparison, Dodge’s own Magnum V-10 engine, introduced in 1994, only made about 450 pound-feet of torque at 2,400 RPM. By 2001, the high-output variant of the turbo diesel offered over 500 pound-feet of torque while keeping peak torque output below 2,000 RPM.

9 Diesel Trucks That Are Surprisingly Affordable To Own

Truck owners deserve cheap to service, dependable trucks.

The Leading Turbo Diesel Platform Has Only Gotten More Capable

The efficiency of the Cummins turbo diesel compared to larger naturally-aspirated platforms became clearer and clearer with every passing year. In commercial applications, every RPM counts, and the benefit of turbocharging in low RPM operation has an undeniable impact. By 1998, Cummins developed the first variable geometry turbocharger (VGT) for a commercial vehicle, pioneering an entirely new era of turbo diesel performance. In 2007, a larger 6.7-liter Cummins turbo diesel was developed that utilized these innovative turbo technologies along with other advancements. This larger and more modern engine would further meet the power demands and emissions regulations of increasingly larger and heavier commercial vehicles.

Pickup Truck

2026

Base MSRP: $$46,725

The Development Of Cummins’ Power And Efficiency

The 6.7-liter Cummins turbo diesel ushered in a new era of diesel performance and produced up to 350 horsepower and 650 pound-feet of torque at a mere 1,500 RPM in manual transmission-equipped examples. Even the 535 pound-feet produced by the rare Viper-powered SRT-10 model via its 8.3-liter V-10 could not match the torque output of the 6.7-liter Cummins engine. The new 6.7-liter variant also received further advancements to its efficiency with the introduction of a six-speed transmission as opposed to the four-speed found on the original 5.9-liter engine. The Dodge Ram 3500 was also the last heavy-duty truck in its class to offer a six-speed manual transmission until the transmission’s discontinuation in 2018.

The integration of the VGT would be one of the largest contributing factors to the increased efficiency and power of the Cummins turbo diesel engine. Though certainly more complex and expensive to produce and repair when compared to its predecessor, the positives provided by the VGT greatly outweighed the negatives. EGR (Exhaust Gas Recirculation), one of the most important emissions systems in diesel engines, greatly benefited from the additional efficiency of VGT technology. With the introduction of DPF (Diesel Particulate Filter) in 2007 and SCR (Selective Catalytic Reduction) in 2013, both the power and efficiency of turbo diesel engines increased. Further benefits of SCR include the doubling of oil service intervals to 15,000 miles.

The Cummins Turbo Diesel Remains A Torque-Producing Demon

By 2013, the 6.7-liter Cummins turbo diesel offered up to 800 pound-feet of torque, and by 2018, that figure reached up to 930 pound-feet of torque. The current high-output variant of the 6.7-liter Cummins found in the 2026 Ram 3500 now produces up to 1,075 pound-feet of torque at only 1,800 RPM. Despite the incredible increase in torque output over the last couple of decades, the Cummins turbo diesel still retains the same fundamental cast-iron block and cylinder head design it did back in the 1980s. While the air and fueling technologies are well ahead of where they started, the simple and robust construction of the Cummins inline-six is what allowed it to become the leader in turbo diesel engines.

10 Diesel SUVs That Offer Incredible Range And Torque

Need an SUV that can tow your boat to the lake without using tonnes of fuel in the process? These diesel-powered SUVs should be on your list.

What To Know About Servicing A Cummins Turbo Diesel

With a 15,000-mile oil service interval, it is already clear why the Cummins turbo diesel is such a desirable power unit in heavy-duty applications. Most Ram 3500 trucks are utilized in commercial applications that often follow specific and strict maintenance schedules. No engine is perfect, and nothing is a greater determining factor in the longevity of an engine than the quality and regularity of its servicing.

A Key Concern With The 6.7-Liter Cummins Turbo Diesel

Since about 2019, the 6.7-liter Cummins turbo diesel engine has achieved stunning torque outputs exceeding 1,000 pound-feet of torque. However, these class-leading power figures do come at a cost, and a known issue with the current generation platform is the valvetrain. Since 1989, the Cummins turbo diesel has utilized flat tappet lifters, but Cummins switched to hydraulic lifters in 2019. Why did Cummins make the switch? Self-adjusting hydraulic lifters do not require valve lash adjustment and offer less operational noise and lower maintenance requirements. While this all sounds positive, these updated lifters began causing failures in an area that had previously been a non-issue for Cummins turbo diesel engines.

Diligent Maintenance Is Key Because Replacement Is Not Cheap

The issue with these hydraulic lifters had to do with the specific design utilized in the construction. If the lifter failure goes unnoticed, the worst result could be catastrophic engine failure. Replacing the short block on a 6.7-liter Cummins diesel can easily run a cost of $10,000 or more, and a complete engine assembly is closer to the $25,000 range. That is an absurd amount of money, and no Cummins owner wants to face the dread of replacing one.

A common solution is replacing the factory lifters with aftermarket solid lifters. This route is still about $1,400 for the parts alone, and it may be necessary to remove the engine for installation. If the engine isn’t pulled, special tooling and expertise are required to perform the procedure in-frame. Another alternative is a flat tappet conversion, which is the style used by the 5.9-liter Cummins, but this is often even more expensive, in the $4,000 range for the parts alone. Then you also have to take into account that these types of aftermarket conversions are not CARB-legal and, as a result, will not pass California smog inspection. While there are more considerations, these are some of the key details you should know about the Ram 3500 and its most popular powertrain, the Cummins turbo diesel. 250,000 miles is very possible with a turbo diesel-equipped Ram 3500, but more care and consideration must be taken now than ever before to ensure reliable operation for years to come.

Sources: Cummins, iSeeCars, Wagler Competition Products, Hamilton Cams