A new invention not much bigger than a fizzy drink promises to revolutionise EV battery technology by dramatically reducing rapid-charging times.

Independent testing by the Warwick Manufacturing Group (WMG) has demonstrated that Dectravalve, a patented, new liquid-cooling technology for electric car batteries, developed by British startup Hydrohertz can reduce the time taken to charge a 100kWh lithium-ironphosphate (LFP) battery from 10% to 80% at 350kW from 30 minutes to just 10.

For an EV with a battery of that size achieving 3.5mpkWh, that would mean adding around 245 miles of range in the time it takes to grab a coffee.

The designers call the system “incredibly cost-effective” and a fraction of the cost of developing entirely new battery packs.

They also claim benefits when the battery is in use during driving: because the cells are operating at optimum temperatures, efficiency increases, giving up to 10% more range, or 3040 miles in a mid-size EV.

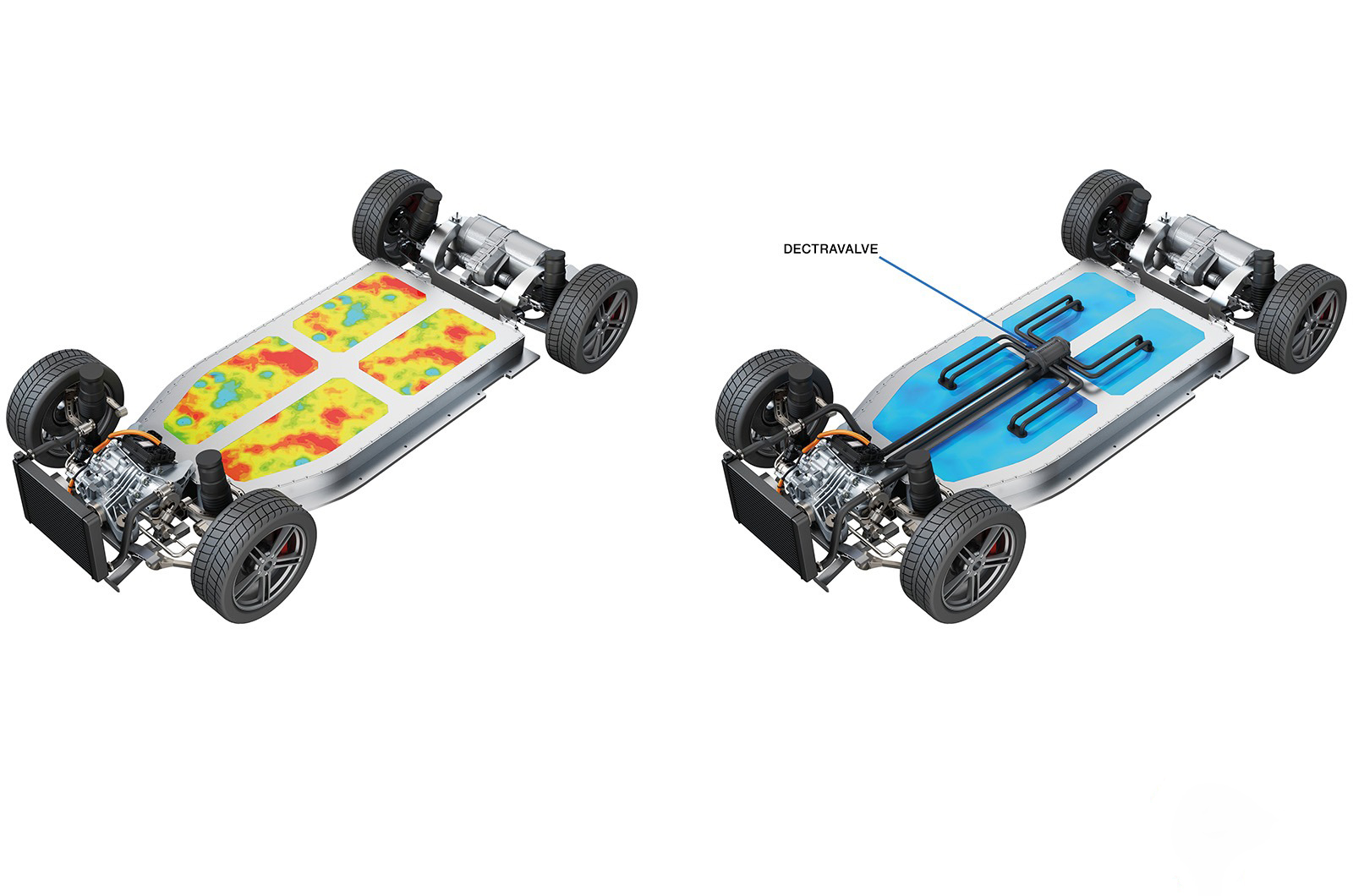

Most EV batteries have cooling channels within them, but during rapid or ultra-rapid charging, it can be a challenge to keep internal temperatures down and evenly spread across all cells.

Typically, say Hydrohertz engineers, temperatures can rise to 56deg C, with a temperature difference across the pack of up to 12deg C in some cases. Once the cell temperature rises above 50deg C, the charge rate must be slowed to avoid damaging cells and reducing battery life, which increases the charging

time. By comparison, during the test at WMG, the hottest cell remained at less than 44.5deg C while the temperature difference across the entire pack was only 2.6deg C.

Battery pack designs vary, but Dectravalve works by controlling the coolant flow to different areas of the battery to maintain even and more effective cooling.

Some existing battery packs are split into four zones, for example, but the zones may be controlled together.

With Dectravalve, the temperature of each zone can be controlled individually to reduce temperatures and maintain an even spread.

So, for example, a battery equipped with Dectravalve made up of 16 modules could be split into four zones of four modules, with Dectravalve controlling four cooling loops individually.

Given the trend in EV architecture to do away with modules and move to cell-to-pack or cell-to-chassis strategies, where cells are installed individually en masse, what happens then?

In that case, Hydrohertz would take a design approach it calls ‘rainbow cooling’, where cooling loops are arranged in the battery one inside the other.

So if the Dectravalve controls four separate cooling circuits, for instance, the first loop would run close to the perimeter of the pack, with the next three arranged one after the other towards the centre of the battery.

And the name? It’s a mashup of the Latin name for 10-legged crustaceans like shrimps (decapod), which 10-port early designs resembled, ‘extra’ for extra capability compared with other systems, and ‘valve’.