A ‘dark factory’, where new cars are produced entirely by robots without human involvement, is set to open as soon as 2030 and revolutionise vehicle manufacturing, according to analysts.

In what may be the biggest shake-up since Ford’s adoption of the moving assembly line to manufacture the Model T in 1913 – cutting production times and costs while lowering showroom prices – the ‘dark factory’ will have serious implications beyond the factory floor.

According to Automotive News, the move could reshape vehicle design principles, workforce training and the economics of car manufacturing through faster model changeovers.

It cites a study by McKinsey suggesting US$150 billion (A$223 billion) in annual ‘economic potential’ could be generated by integrating robotics and artificial intelligence (AI) into manufacturing.

CarExpert can save you thousands on a new car. Click here to get a great deal.

Advantages on the factory floor include a robot’s ability to change tasks and perform processes humans cannot, while also not suffering fatigue – or, as experienced at Ford in the 1910s, boredom from repetitive jobs.

These factors also reduce the likelihood of errors compared with human production-line workers, improving manufacturing efficiency as well as the quality of the finished vehicle.

The use of robotics in vehicle production and development is far from new.

Ford Australia even used robot test drivers in the development of its Ranger Super Duty ute which went on sale late last year.

Nevertheless, there’s an increasing focus on humanoid robots in vehicle production, something that’s expected to culminate in the first ‘dark factory’.

Analysts at tech firm Gartner, as well as Warburg Research, told Automotive News several major automotive players “are already setting up disruptive manufacturing processes and reveal more of a focus on humanoid robots”.

At least a dozen leading automakers are testing advanced robotics in their factories, and according to Gartner vice president of research Pedro Pacheco, a fully robotised ‘dark factory’ is likely to open by “the end of this decade”.

“Recognisably, at the moment they don’t have a major impact on vehicle assembly. However, it’s likely their capabilities will progress throughout this decade, given the major focus dedicated by so many automakers,” Mr Pacheco said.

Gartner analyst Marco Sandrone told Automotive News the only parts of the vehicle manufacturing process not fully automated are the installation of wiring harnesses and interior components.

Companies within the automotive supply chain with publicised plans to use humanoid robots include Tesla and BYD.

BMW has already been collaborating with robotics company Figure AI. The company touted in November that an 11-month deployment of its Figure 02 robot saw it run 10-hour shifts five days a week loading 90,000 parts and contributing to the production of over 30,000 X3s.

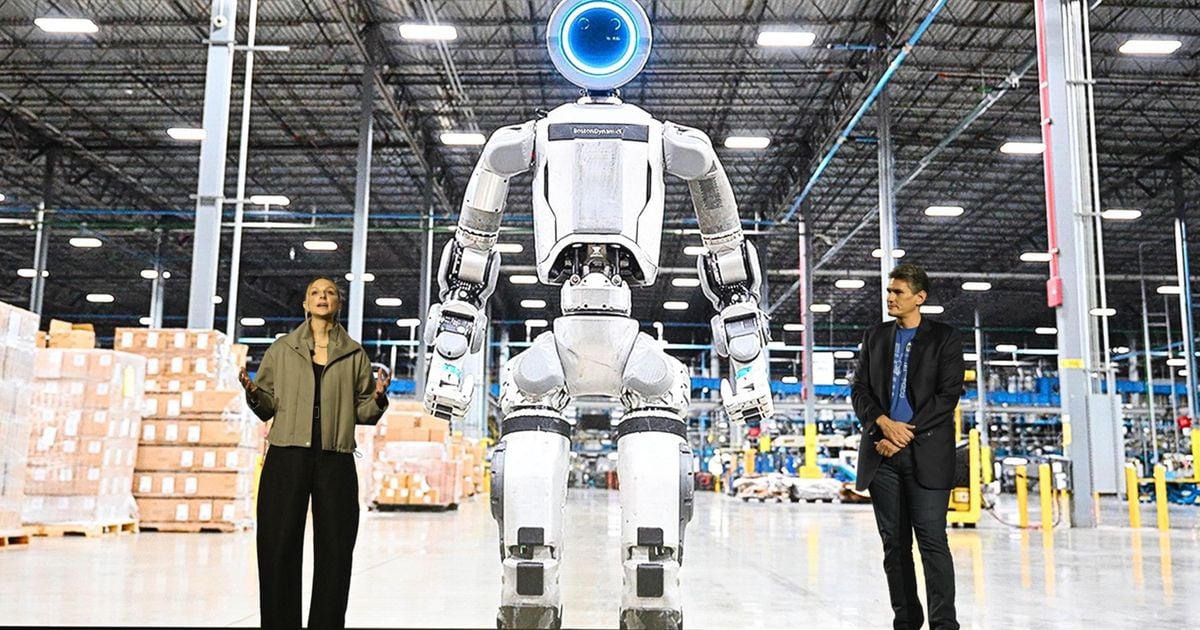

Hyundai is planning to use its Boston Dynamics robots at its Georgia, US, plant from 2028.

It showed its ‘Atlas’ humanoid robot at the Consumer Electronics Show (CES) in Las Vegas earlier this month, saying it “plans to integrate Atlas across its global network”.

Hyundai Motor Group (HMG) bought an 80 per cent stake in Boston Dynamics in 2021, saying the two companies were working on a ‘robotics value chain’ to help build cars faster while maintaining safety.

The Korean automaker said robots offer “opportunities for rapid growth and the potential to positively impact society by making work safer and more productive”.

Robots are already in use at Hyundai’s ‘smart factory’ for electric vehicles in Singapore, which opened in 2023 “with integration between humans, robotics and AI technology”.

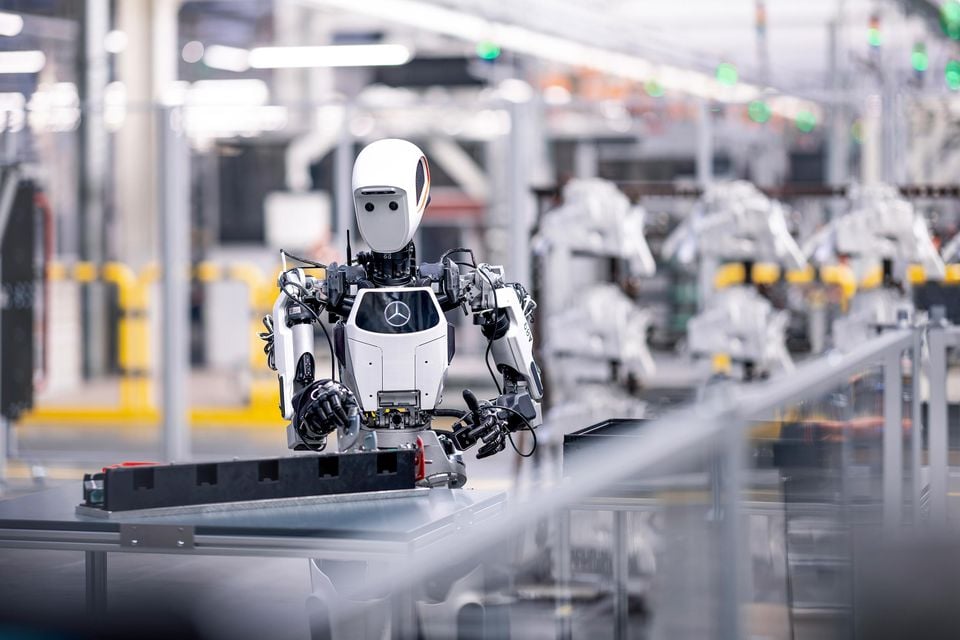

Mercedes-Benz is testing humanoid robots in its factories, with a 2025 announcement outlining plans to have its ‘Apollo’ robots, made by Apptronik, interact with humans.

“Around 2030 we will see at least some humanoid robots in production,” said the automaker’s production boss, Jörg Burzer.