It seems that every automaker that’s taking the electric vehicle (EV) market seriously is making bold promises about solid-state batteries (SSB). The so-called “holy grail” of battery technology will supposedly make EVs achieve a similar range figure as an internal combustion engine (ICE) car, but in a smaller, lighter, and safer format than today’s current crop of lithium-ion or lithium-iron-phosphate (LFP) batteries.

We’ve been hearing it for years now, with every EV manufacturer seemingly one step closer to achieving commercial viability. So far, however, it is Mercedes-Benz who’s the closest due to prototypes already undergoing road testing. Toyota, on the other hand, probably has the boldest promises, but has yet to put an SSB into prototype testing. What’s the difference between the two companies, and which one is emerging to be the most promising so far?

This Is When Solid-State Batteries Are Expected To Become Mainstream

After many years of waiting, the time for solid-state batteries could finally be here.

Mercedes-Benz’s Outsourced Battery

One key difference with Mercedes-Benz‘s SSB endeavors is their reliance on a third-party battery company. In this case, Mercedes-Benz already has an ongoing relationship with Factorial Energy, an American SSB startup where other companies like Stellantis also have partnerships.

Factorial Energy’s Cells

The battery of the prototype EQS that’s being used for road testing features an SSB developed by Factorial Energy. Their partnership in 2021 allowed Mercedes-Benz to fast-track SSB development. Developing one from scratch would be time-consuming, but this partnership that’s been going on for four years now is why we now have an EQS prototype undergoing SSB road testing.

Factorial Energy brands their SSB as Solstice. Since it is an SSB, it has zero liquid for its electrolyte, which is the main component that makes SSBs thermally stable and thus, very safe. According to Factorial Energy’s own research, a current 90 kWh battery offers 200 to 300 miles of range, as well as a weight of 800 pounds. Their Solstice SSB, on the other hand, promises a range of 500 to 600 miles, whilst weighing 580 pounds. Lighter, but with even more range, is the main driver for EV manufacturers pushing for SSBs.

Interestingly, It’s Passively Cooled

Keeping battery health and longevity in check is today’s innovation in battery thermal management. That’s exactly why you now have heat pumps for the battery during the winter, as well as liquid cooling when the outside temperature gets hot—all in the pursuit of optimizing the battery’s performance. Interestingly, the EQS’s SSB is passively cooled, meaning it doesn’t have active thermal management.

The lack of active thermal management saves on battery energy, and it’s one of the major reasons why Mercedes-Benz can promise as much as 621 miles of range. However, it’s interesting to see if this means that SSBs truly don’t need active thermal management. Another ingenious trick that Mercedes developed together with their Mercedes-AMG High Performance Powertrains (HPP) division is pneumatic actuators, which interact with the SSB’s changes in cell volume during charging and discharging. When the battery charges, the cells expand, but when it discharges, the cells shrink.

The Science Behind Honda’s Solid-State Battery Breakthrough

Honda may become the first car company to get an all-solid-state battery into an actual car. Here is how they’re doing it.

Toyota’s (Mostly) In-House Work

On the other hand, Toyota’s SSB developments are mostly made in-house. The keyword here is mostly, since Toyota still does collaborative work with suppliers to gather knowledge and speed up their in-house SSB development.

Over 1,000 Patents With Panasonic

Toyota’s SSB bets are in collaboration with Panasonic. The two companies have so far developed more than 1,000 patents for their SSB chemistry. Further integrating SSB development into Toyota’s own backyard is their acquisition of Primearth EV Energy (PEVE) from Panasonic in 2024. Toyota has another affiliate company called Prime Planet Energy & Solutions, in which the Japanese automaker has a 51 percent stake, and the remaining 49 percent with Panasonic. Prime Planet Energy & Solutions already makes EV batteries, while PEVE’s EV battery production is only ramping up.

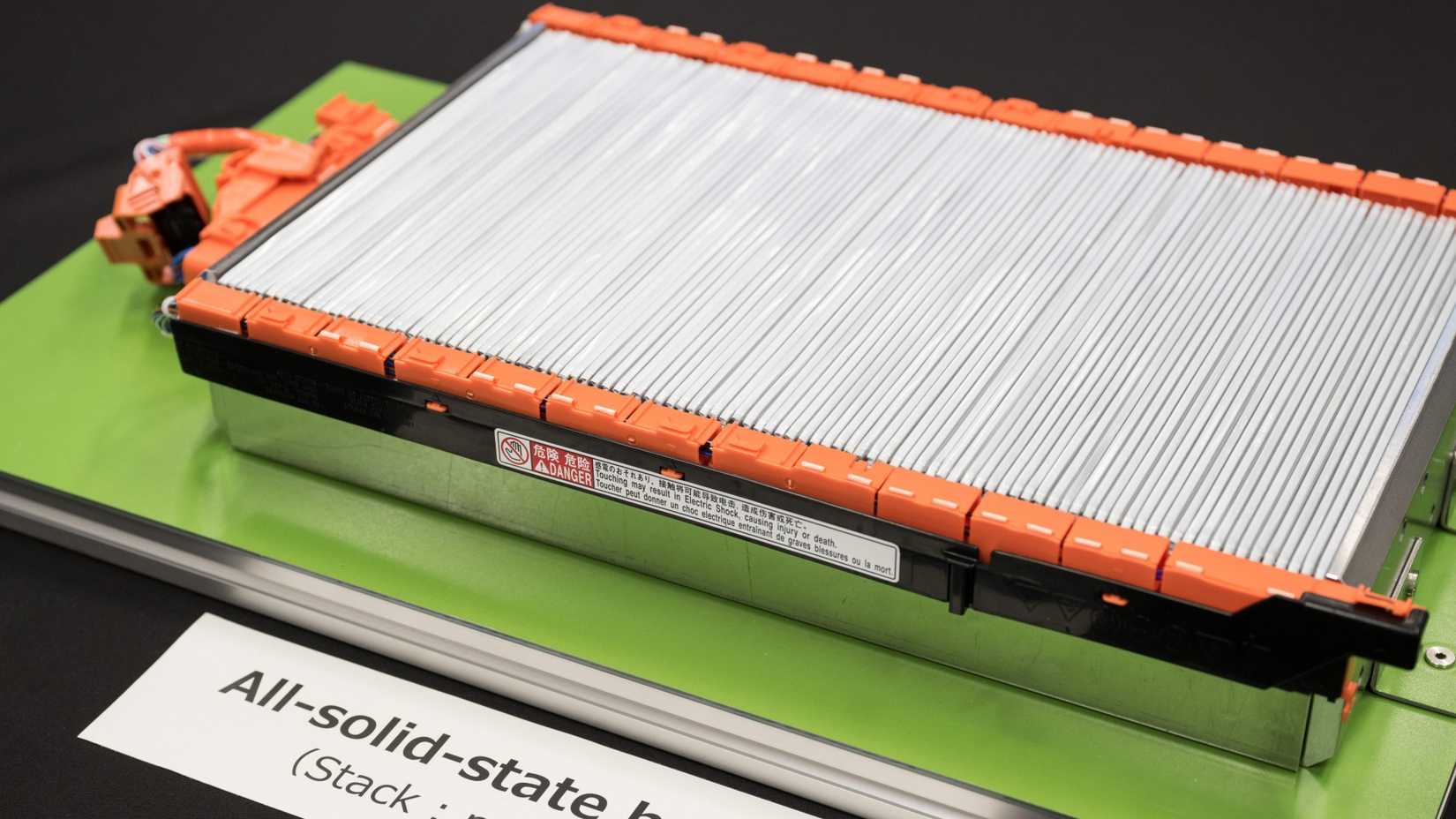

Toyota’s developments in SSBs actually date back to 2012, but they barely received media coverage due to the world’s attention to Tesla’s revolutionary Model S at the time. Between 2012 and 2020, Toyota’s focus on SSBs dwindled, only speeding up once again as they got closer to working prototypes.

In-House Manufacturing, Outsourced Raw Materials

Toyota aims to produce its own SSBs, rather than contracting with outside manufacturers, but Toyota won’t directly extract those raw materials. Instead, that’s where Idemitsu Kosan comes in. Idemitsu Kosan, a large petroleum company in Japan, will strengthen its materials business for Toyota’s SSB production plans. Idemitsu Kosan is building a new lithium-sulfide plant, which has a planned completion date of June 2027, just in time for Toyota to finally produce all-solid-state batteries based on its timeline.

The Two Companies’ Current Progress

For now, the difference between their SSBs mostly has to do with their development paths. Mercedes-Benz invested in an SSB startup, while Toyota is developing SSBs in-house by acquiring the knowledge and resources. Here’s what’s currently happening between the two companies when it comes to their SSB development.

Road Testing For Mercedes-Benz

Immediately obvious is Mercedes-Benz’s lead in the SSB race—at least relative to Toyota. Mercedes-Benz’s outsourcing strategy has helped the German automaker be at the forefront of SSB development. Of course, with real-world testing comes interesting data to analyze, and in this case, Mercedes-Benz already has interesting findings.

Last September, Mercedes-Benz put the EQS to a range test, driving from Stuttgart, Germany, to Malmö, Sweden, covering a distance of 748.8 miles—far longer than any EV in production. At least when evaluating their EPA estimates. That’s because the Lucid Air Grand Touring was able to achieve the same Guinness World Record-certified distance with just a standard lithium-ion battery. In Lucid’s case, though, it has to do with their EV drivetrain’s incredible efficiency, which the EQS isn’t. If the Lucid Air Grand Touring had an SSB, imagine the range possibilities of that vehicle.

Toyota Continues To Gather Resources

On the other hand, Toyota is still in the development phase for its SSBs, since it has not yet brought a vehicle on the road for testing purposes. Or at least from what we know publicly. Perhaps they’re already doing internal testing within the company’s closed courses with a vehicle prototype that they haven’t publicized yet.

For now, Toyota continues to gain knowledge and manufacturing expertise for SSBs, as we have yet to see an SSB from Toyota being put through its paces on public roads. On the upside, the in-house development approach to development and manufacturing means Toyota will have greater control over the SSB’s quality improvements and manufacturing output.

Source: Mercedes, Toyota